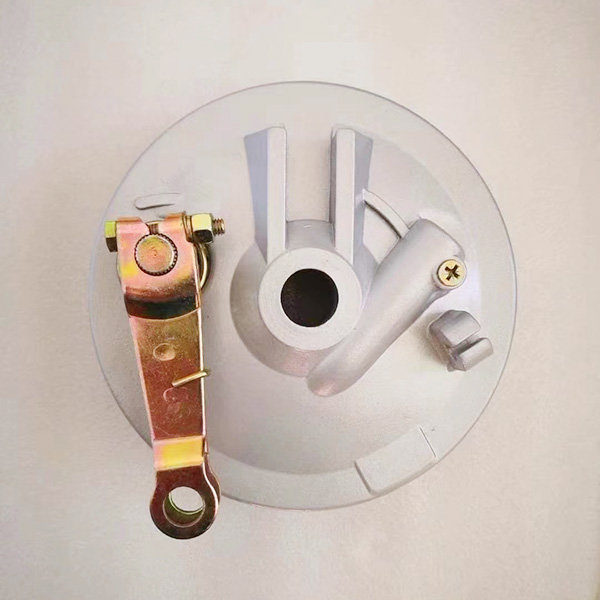

Front brake assembly

The front brake assembly is a critical element of a vehicle’s braking system,essential for safe and effective stopping power.Proper maintenance and timely replacement of components are vital to ensure the vehicle’s braking system performs optimally.

The front brake assembly is a crucial component of a vehicle's braking system, responsible for slowing down or stopping the vehicle. It comprises various parts that work together to deliver effective braking performance, playing a significant role in vehicle safety and handling. Since the front brakes typically handle a larger portion of the braking force, their proper function is essential for overall vehicle control.

Key Components:

Brake Calipers:

Function: House the brake pads and apply pressure to the brake rotors, creating friction to slow down the vehicle.

Types: Available as single-piston or multi-piston (floating or fixed) depending on design and braking requirements.

Brake Rotors (Discs):

Function: The rotating disc that the brake pads press against to generate friction and slow the vehicle.

Design: Can be vented, slotted, or drilled to enhance heat dissipation and performance.

Brake Pads:

Function: The friction material that presses against the brake rotors to create the necessary friction for slowing or stopping.

Types: Includes organic, semi-metallic, and ceramic materials, each with unique performance characteristics.

Brake Lines and Hoses:

Function: Carry brake fluid from the master cylinder to the brake calipers.

Material: Typically made of reinforced rubber or braided steel for durability and flexibility.

Brake Master Cylinder:

Function: Generates hydraulic pressure to operate the brake calipers, usually located in the engine compartment.

Design: Contains a reservoir for brake fluid and a piston mechanism that transfers force from the brake pedal to the calipers.

Brake Fluid:

Function: Transmits force from the brake pedal to the calipers through hydraulic pressure.

Types: Various types available (e.g., DOT 3, DOT 4, DOT 5.1), each with different properties for temperature and moisture resistance.

Brake Booster (for vehicles with power brakes):

Function: Uses vacuum or hydraulic pressure to assist the driver in applying the brakes, reducing pedal effort.

Design: Typically located between the master cylinder and brake pedal.

Types of Front Brake Systems:

Disc Brakes:

Description: Common in modern vehicles, consisting of a rotor and caliper; the caliper squeezes the brake pads against the rotor to create friction.

Advantages: Better heat dissipation and consistent performance compared to drum brakes.

Drum Brakes:

Description: Less common for front brakes, consisting of a rotating drum and brake shoes that press against the inside surface.

Advantages: Generally cheaper but less efficient in heat dissipation than disc brakes.

Advantages of Front Brake Assembly:

Enhanced Safety: Provides reliable stopping power and vehicle control, especially in emergency situations.

Improved Performance: Modern disc brake systems offer superior heat dissipation and fade resistance compared to older drum systems.

Durability: Designed to withstand the heat and stress generated during braking, contributing to overall vehicle safety.

Installation and Maintenance:

Installation:

Typically performed by automotive technicians, involving the replacement of worn components and ensuring proper alignment.

Maintenance:

Regular inspections are crucial. This includes checking brake pads for wear, ensuring rotors are not excessively worn or warped, and maintaining proper brake fluid levels.

Safety Considerations:

Regular Checks: Inspect the brake system for signs of wear, such as squeaking or grinding noises, reduced braking performance, or vibrations.

Brake Fluid: Check and replace brake fluid regularly, as it can absorb moisture over time, affecting braking performance.

Brake Pads and Rotors: Replace brake pads and rotors according to the manufacturer’s recommendations to ensure optimal performance and safety.