Why Brake Assembly Diagnostics Are Critical

Brake assemblies are the backbone of commercial vehicle safety. Trucks, trailers, and buses operate under high loads and harsh conditions, making their braking systems prone to wear and failure. Issues such as abnormal noise and overheating not only increase maintenance costs but also pose significant safety risks. Regular diagnostics and timely interventions are essential for ensuring efficiency and preventing accidents.

Common Brake Assembly Failures in Commercial Vehicles

· Brake Noise – Often caused by uneven wear, poor-quality pads, or loose components.

· Overheating – Results from excessive braking force, poor ventilation, or worn rotors.

· Vibration or Pulsation – Indicates misalignment or warped brake discs.

· Reduced Braking Power – Caused by contaminated brake linings or hydraulic leaks.

· Premature Wear – Low-grade materials or improper installation accelerate component failure.

Diagnosing Noise Problems in Brake Assemblies

1. Inspect Brake Pads and Linings – Look for uneven or excessive wear.

2. Check Rotor Surface – Grooves or scoring indicate poor contact with pads.

3. Examine Hardware and Fittings – Loose bolts and pins can cause rattling or squealing.

4. Evaluate Material Quality – Low-quality aftermarket parts often generate noise.

5. Test in Different Conditions – Noise during light braking may signal glazing, while heavy-load noise suggests overheating.

Diagnosing Overheating in Brake Assemblies

· Measure Rotor Temperature – Overheating rotors discolor and lose hardness.

· Check Brake Balance – Unequal braking force increases heat on one side.

· Inspect Cooling Pathways – Blocked vents reduce heat dissipation.

· Examine Driving Patterns – Excessive downhill braking without engine braking leads to thermal stress.

· Verify Proper Lubrication – Dry or contaminated caliper slides increase friction and overheating.

Preventive Maintenance Strategies

· Usehigh-quality brake pads and rotors designed for heavy-duty vehicles.

· Performregular cleaning and lubrication of calipers and pins.

· Rotate and replace brake components based on mileage and load history.

· Train drivers onengine braking techniques to reduce overheating.

· Conduct routine inspections to detect early signs of failure before breakdowns occur.

Buying Guide for Importers and Distributors

· Partner with Certified Manufacturers – Ensure compliance with ISO/SAE standards.

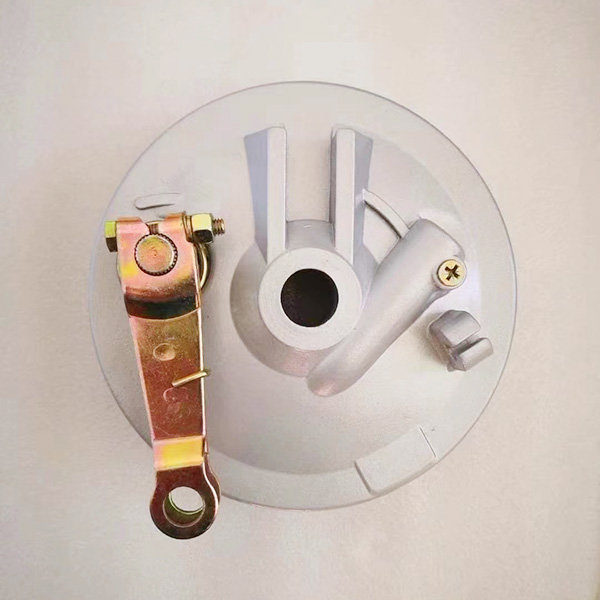

· Offer Full Brake Assembly Kits – Provide pads, rotors, calipers, and hardware for convenience.

· Focus on Material Innovation – Promote heat-resistant and noise-reducing components.

· Provide Testing Reports – Customers value proof of durability and performance.

· Balance Pricing with Reliability – Cost-efficient bulk orders with strong warranties attract fleet operators.

Conclusion

Commercial vehicle brake assembly failures, especially noise and overheating, can be diagnosed effectively through systematic inspection and preventive strategies. For importers and distributors, sourcing reliable, high-quality brake solutions ensures customer safety while strengthening competitiveness in the global market.

Meta Description:

Explore a comprehensive guide to diagnosing commercial vehicle brake assembly failures. Learn how to solve noise and overheating issues with effective inspection, maintenance, and sourcing strategies.