Introduction to Custom Brake Assemblies

Special vehicles, including heavy-duty trucks, construction machinery, and specialty transport units, demandhigh-performance braking systems tailored to their unique operating conditions. Off-the-shelf brake assemblies often fail to meet these requirements, makingcustom brake solutions essential for safety, reliability, and efficiency. OEM-supported custom assemblies ensure that these specialized systems meet strict engineering standards while providing long-term performance and compliance with vehicle regulations.

Why Custom Brake Assemblies Are Essential

Custom brake assemblies are designed to address specific challenges that standard braking systems cannot:

1. Unique Load Requirements: Special vehicles often carry irregular or heavy loads that require reinforced brake components.

2. Extreme Operating Conditions: Vehicles operating in construction sites, mining, or off-road environments need heat-resistant and durable braking materials.

3. Precise Performance Tuning: Custom assemblies allow OEMs to optimize braking force distribution, response time, and pedal feel for specialized applications.

4. Regulatory Compliance: Custom solutions can be engineered to meet local and international safety standards, ensuring legal operation in various markets.

5. Integration with Vehicle Systems: Modern custom brakes are designed to work seamlessly with ABS, traction control, and electronic braking systems (EBS).

By addressing these factors, OEM-supported custom brake assemblies provide superior performance, safety, and operational efficiency.

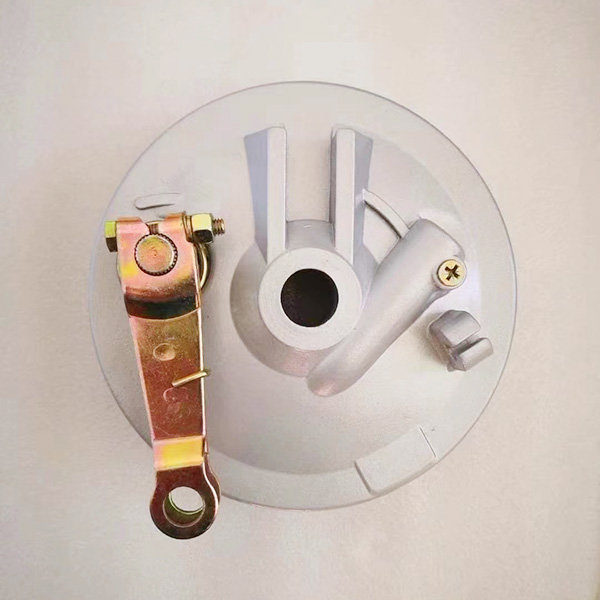

Components of a Custom Brake Assembly

A fully engineered brake assembly typically includes:

· Brake Calipers: Designed for precise clamping force and heat dissipation.

· Brake Discs or Drums: Tailored material composition for wear resistance and thermal stability.

· Brake Pads or Shoes: Specialized friction materials to match vehicle load and application.

· Hydraulic or Pneumatic Systems: Customized to ensure consistent brake actuation.

· Mounting Hardware and Sensors: OEM-grade components that ensure proper alignment, monitoring, and system integration.

Each component is carefully selected and tested to deliver consistent performance under demanding conditions.

Benefits of OEM-Supported Custom Solutions

1. Guaranteed Compatibility: OEM support ensures the custom assembly integrates seamlessly with the vehicle’s existing systems.

2. Higher Reliability: Components are engineered and tested for durability under real-world conditions.

3. Performance Optimization: Braking performance is tailored to the vehicle’s specific weight, load, and operational environment.

4. Reduced Maintenance Costs: High-quality materials and precision manufacturing minimize wear and the frequency of replacements.

5. Enhanced Safety: Custom assemblies provide predictable stopping power, critical for both operator and cargo safety.

OEM collaboration ensures adherence to stringent quality standards and reduces the risk of system failure in critical applications.

Applications of Custom Brake Assemblies

Custom brake solutions are widely used in special vehicles, including:

· Heavy-Duty Trucks and Trailers: Handling extreme loads and long-distance travel.

· Construction and Mining Vehicles: Operating in dusty, wet, or high-temperature environments.

· Agricultural Machinery: Providing safe braking under uneven terrain and variable load conditions.

· Emergency and Utility Vehicles: Ensuring quick response and reliable stopping power in critical situations.

· Specialty Transport Vehicles: Including refrigerated units, tankers, and oversized load carriers that require precise braking control.

How to Choose the Right Custom Brake Solution

When selecting a custom brake assembly, consider the following factors:

1. Vehicle Specifications: Weight, load type, operating environment, and braking system requirements.

2. OEM Support Level: Confirm that the supplier provides genuine OEM support for parts, design, and integration.

3. Material and Performance Standards: Ensure components meet international safety certifications (ISO, SAE, ECE).

4. Maintenance and Service Availability: Check availability of replacement parts and technical support.

5. Cost vs. Longevity: Invest in assemblies that provide long-term reliability, reducing overall operational costs.

Future Trends in Custom Brake Solutions

The evolution of brake technology for special vehicles includes:

· Advanced Friction Materials: Improved wear resistance and heat tolerance.

· Electronic and Adaptive Systems: Integration with vehicle control systems for predictive braking.

· Lightweight Components: Reducing unsprung mass while maintaining performance.

· Sustainable Manufacturing: Using eco-friendly materials and processes for reduced environmental impact.

These trends indicate that custom brake assemblies will continue to enhance safety, efficiency, and reliability for specialized vehicle applications.

Conclusion: Investing in Safety and Performance

Custom brake assembly solutions, especially those supported by OEMs, are critical for special vehicles that operate under challenging conditions. From heavy-duty trucks to specialty machinery, these systems provide superior braking performance, long-term durability, and regulatory compliance. Choosing the right OEM-backed solution ensures safety, operational efficiency, and cost-effective maintenance, making it a smart investment for any fleet or specialty vehicle operator.

Meta Description:

Explore OEM-supported custom brake assembly solutions for special vehicles. Learn how tailored components enhance safety, durability, and performance for heavy-duty trucks, construction, and specialty machinery.