Understanding OEM Brake Assemblies and Their Alternatives

Original Equipment Manufacturer (OEM) brake assemblies are designed and produced to meet the exact specifications of vehicle manufacturers, ensuring optimal fit and performance. However, OEM parts can be costly and sometimes hard to source in certain regions. This has led to a growing market for alternative brake assemblies that offer comparable quality at more competitive prices, making them attractive for global buyers and distributors.

Benefits of Choosing OEM Brake Assembly Alternatives

Cost Savings Without Compromising Quality

Many aftermarket brake assemblies are manufactured using high-grade materials and advanced processes, providing reliable performance at a fraction of OEM costs.

Wider Availability and Faster Lead Times

Alternatives often come from suppliers with flexible production capacities and diverse distribution networks, reducing wait times and improving supply chain reliability.

Compatibility with Multiple Vehicle Models

Some alternative assemblies are designed to fit a range of vehicles, offering buyers versatile inventory options and easier stock management.

How to Identify Quality OEM Brake Assembly Alternatives

Verify Manufacturer Certifications

Look for ISO/TS 16949, SAE, or other recognized automotive quality certifications to ensure product reliability and safety.

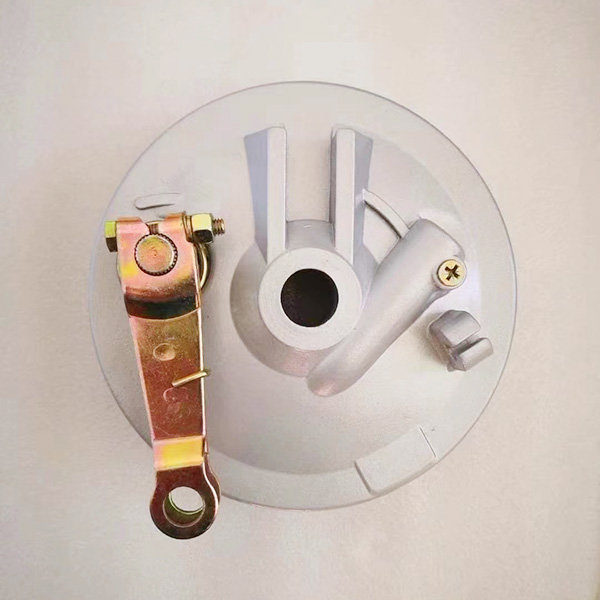

Assess Material and Component Standards

High-quality alternatives use durable cast iron, carbon composites, or alloy steels for brake drums and discs, paired with friction materials tested for longevity and heat resistance.

Check for Warranty and Support

Reputable suppliers provide warranties and after-sales services, reflecting confidence in their product quality.

Request Product Samples and Test Reports

Evaluating samples and reviewing independent test data helps verify that alternatives meet required performance standards.

Global Sourcing Tips for Cost-Effective Brake Assemblies

Partner with Experienced Exporters

Choose suppliers familiar with international shipping regulations and customs to avoid logistical delays and extra costs.

Negotiate Bulk Pricing and Flexible MOQ

Many manufacturers offer discounts for large orders or flexible minimum order quantities to support small and medium-sized buyers.

Use Online B2B Platforms and Trade Shows

Platforms like Alibaba, Global Sources, and participation in industry trade shows can help identify reliable alternative brake assembly suppliers.

Maintain Quality Control Procedures

Establish inspection protocols before shipment to ensure consistent product quality and reduce returns or complaints.

Meta Description

Discover cost-effective OEM brake assembly alternatives with this global sourcing guide. Learn how to find quality aftermarket options, verify suppliers, and optimize purchasing for international buyers.