Introduction to Trailer Jack Compatibility

Trailer jacks are essential for lifting, stabilizing, and maneuvering trailers safely and efficiently. However, to maximize their effectiveness, it is crucial to ensurecompatibility with other trailer equipment, including hitches, couplers, and trailers of various sizes. Proper matching not only improves operational efficiency but also enhances safety and prolongs equipment lifespan.

Understanding Trailer Jack Types and Specifications

Trailer jacks come in various types, each designed for specific applications. Understanding these types helps in selecting compatible equipment:

1. Manual Crank Jacks

· Operated by hand and ideal for small to medium trailers.

· Compatibility depends on load capacity and mounting style.

2. Hydraulic Jacks

· Offer effortless lifting for heavier trailers.

· Ensure the jack’s hydraulic capacity matches the trailer’s tongue weight.

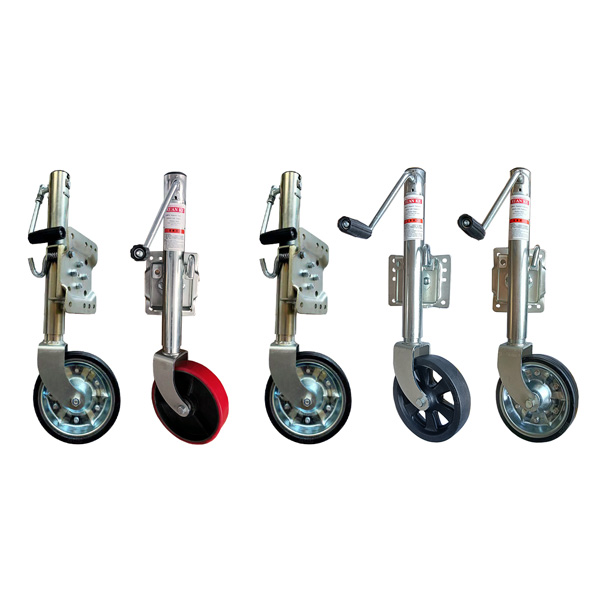

3. Swivel Jacks with Wheels

· Provide mobility and easy maneuvering in tight spaces.

· Check wheel size and swivel design to match trailer terrain and clearance.

Matching Trailer Jacks with Trailer Hitches

Trailer jacks must work seamlessly with your hitch to ensure proper lifting and stability:

· Tongue Height: Measure the height of your trailer tongue and choose a jack with an adjustable lift range.

· Mounting Style: Confirm whether the jack mounts to the trailer frame or directly to the coupler.

· Weight Capacity: Select a jack rated for the trailer’s fully loaded tongue weight.

· Clearance: Ensure the jack does not interfere with hitch operation or towing components.

Ensuring Compatibility with Trailer Couplers

Trailer couplers vary by type, including ball couplers, pintle hooks, and specialized adapters.

Compatibility Tips:

· Verify that the jack’s footplate or wheel does not obstruct coupler engagement.

· Ensure smooth vertical movement to lift and lower the coupler safely.

· Consider using a jack with a swivel mechanism if the trailer requires angled positioning.

Matching with Other Trailer Equipment

Trailer jacks often need to work in conjunction with additional equipment such as stabilizer jacks, wheel chocks, and towing accessories.

1. Stabilizer Jacks: Ensure the trailer jack’s base does not collide with stabilizer pads during operation.

2. Wheel Chocks: Provide additional safety when lifting or parking trailers; confirm clearance for jack operation.

3. Trailer Frames: Verify mounting holes and bracket compatibility to secure the jack firmly.

Maintenance for Optimal Compatibility

· Regular Inspections: Check mounting points, bolts, and brackets for wear.

· Lubrication: Keep moving parts smooth to maintain proper operation with connected equipment.

· Alignment Checks: Ensure the jack remains perpendicular and stable to avoid misalignment with the trailer and hitch.

Benefits of Proper Compatibility

· Enhanced Safety: Reduces the risk of tipping, instability, or equipment damage.

· Operational Efficiency: Smooth lifting, lowering, and maneuvering save time and effort.

· Extended Equipment Lifespan: Reduces strain on the jack, hitch, and trailer frame.

· Versatility: Compatible jacks can be used across multiple trailers with minimal adjustments.

Conclusion: Choosing the Right Trailer Jack for Maximum Compatibility

Selecting a trailer jack that is fully compatible with your hitch, coupler, trailer frame, and additional equipment ensures safe, efficient, and long-lasting operation. Consider load capacity, mounting style, and adjustable features when making your choice. Properly matched equipment improves operational efficiency, protects your trailer and accessories, and provides peace of mind during every towing or parking scenario.

Meta Description:

Learn how to match trailer jacks with hitches, couplers, and other trailer equipment. Ensure compatibility for safe, efficient, and long-lasting trailer operation.